On Labour, Unions and 3D Printing

Indeed, the U.S.’ manufacturing sector, much like its agricultural one, has declined in demand over the past century.

That is namely due to the advent of mechanization and technology. As a result, many of the remaining jobs have been outsourced to developing countries — an apparent standard for most developed nations.

A fabled story about the late Apple founder Steve Jobs involves an exchange he had with President Obama at a breakfast with other “titans of Silicon Valley.” Obama asked Jobs what it would take to make iPhones in the U.S. Jobs replied: “Those jobs are gone. And they’re not coming back.”

The negative impact of this shift is a loss of low-skilled jobs back home. The positive side is that it pushes the job requirements further up the value chain. Jobs followed up his comment with an oft-overlooked statistic: There are more people working in North America designing and developing apps than there ever were involved in the local manufacturing of devices.

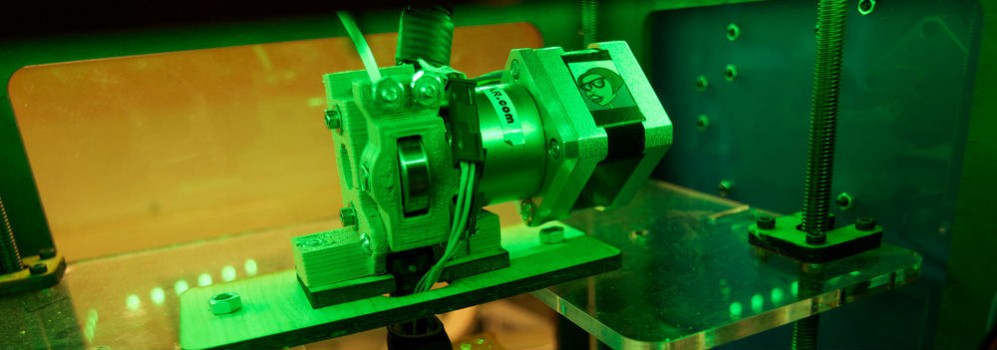

Additive printing technology has the potential to create similar new labour markets within the manufacturing industry. The technology could create more demand for skilled workers such as industrial designers and inventory managers, as well as create completely new roles from scratch.

Backlash and Complications

The process of 3D printing undoubtedly threatens low-wage jobs both at home and overseas, but it also has the potential to complicate higher-value roles.

For example, an inventory manager will be required to have quite different skills and prerequisites based on whether he’s applying for work at a traditional manufacturing firm or at a firm using 3D printing. This inherent threat, along with the recent attention given to 3D printing in the press, may be a signal for labour groups to begin mobilizing a defence.

Econolyst’s Reeves told Arbitrage Magazine about the only 3D printing-related labour issue he had come across. It involved an American automotive manufacturing firm.

Like most car manufacturers, the company had been using additive technology for decades, but solely for prototyping purposes. Then, they decided to start using the technology for the actual production of low-value components. The unions fought this decision. They claimed that the people who worked in the model shop were “model-makers” and not “manufacturers.” These model-makers belonged to a higher pay-grade than that of manufacturers, and the unions argued it was unacceptable for these workers to be subject to lower-value manufacturing work.

As 3D printing becomes more widely used, it seems an ambiguity in the definition of labour roles will naturally take root, blurring the lines between areas such as manufacturing, product development and retail services. How people label themselves will affect things like their pay and skill requirements. Health and safety guidelines may also become an issue down the line as more people begin to work with the technology. There currently is little information available on such guidelines.

Another potential issue facing 3D printing is the misapplication of its technology. In addition to manufacturing, construction is another industry that could potentially be disrupted by additive processes. There have been many one-off projects of 3D-printed buildings these projects feel more like novelties than case studies that can be replicated and scaled.

Reeves suspected that the idea of applying 3D printing to construction activities seemed like a nonsensical premise. He recalled that the construction industry has been making things in layers for two-and-a-half thousand years. It started with the Egyptians and the pyramids; and, even today, most brick buildings are still made in layers. Reeves doubted the logic of bringing to a site a machine that’s bigger than the building to be made.

“There’s little evidence of anything particularly useful in the construction domain,” Reeves says.

Share the post "On Labour, Unions and 3D Printing"